I. Foundational Definition and Core Purpose

I. Foundational Definition and Core Purpose

RNA extraction kits are standardized biochemical systems designed to isolate high-integrity RNA from diverse biological matrices while eliminating contaminants (DNA, proteins, lipids). These kits provide:

- RNase-free workflow: Integrated inhibitors prevent RNA degradation during processing

- Target specificity: Selective capture of all RNA classes (mRNA, tRNA, rRNA, miRNA)

- Downstream compatibility: Purified RNA ready for PCR, sequencing, or microarray analysis

(Fig. 1: RNA Extraction Ecosystem)

Description: Central icon: RNA helix. Surrounding modules: Sample types (cells, tissues, biofluids), contaminants removed (DNA/proteins), output applications (NGS, qPCR, microarrays).

II. Core Biochemical Components

A. Essential Reagents

| Component | Function | Concentration Range |

|---|---|---|

| Chaotropic salts (Guanidine HCl) | Denature proteins/RNases | 4–6 M |

| Reducing agents (β-mercaptoethanol) | Disrupt disulfide bonds | 0.1–1.0 M |

| Surfactants (SDS, Triton X-100) | Membrane lysis | 0.1–2.0% |

| RNase inhibitors (Diethylpyrocarbonate) | Block RNase activity | 0.01–10.00 M |

| Nucleic acid binders | Silica matrices/magnetic beads | Varies by format |

B. Physical Separation Systems

- Spin-column technology:

- Silica membranes bind RNA at high chaotrope concentrations

- Contaminants removed via ethanol washes

- RNA eluted in low-ionic-strength buffers

- Magnetic bead systems:

- Paramagnetic particles with oligo-dT/silica coatings

- High-throughput automation compatibility

(Fig. 2: Separation Mechanism)

Description: Left: Cross-section of spin column showing RNA (red) bound to silica membrane. Right: Magnetic beads capturing RNA in solution while contaminants remain.

III. Workflow Architecture

Standardized Procedure

1. **Lysis**: Homogenize sample in chaotropic buffer (3–5 min)

2. **DNA removal**: On-column DNase digestion (15 min)

3. **Binding**: RNA adsorption to silica/magnetic surfaces (5 min)

4. **Washing**: Ethanol-based impurity removal (2×5 min)

5. **Elution**: Nuclease-free water recovery (2 min)

Total time: 30–40 minutes for 12 samples

Critical Innovations

- gDNA elimination columns: Remove genomic DNA without DNase treatment

- Cross-linking reversal: Specialized buffers for FFPE samples

- Micro-scale adaptation: Optimized for 10–100,000 cells

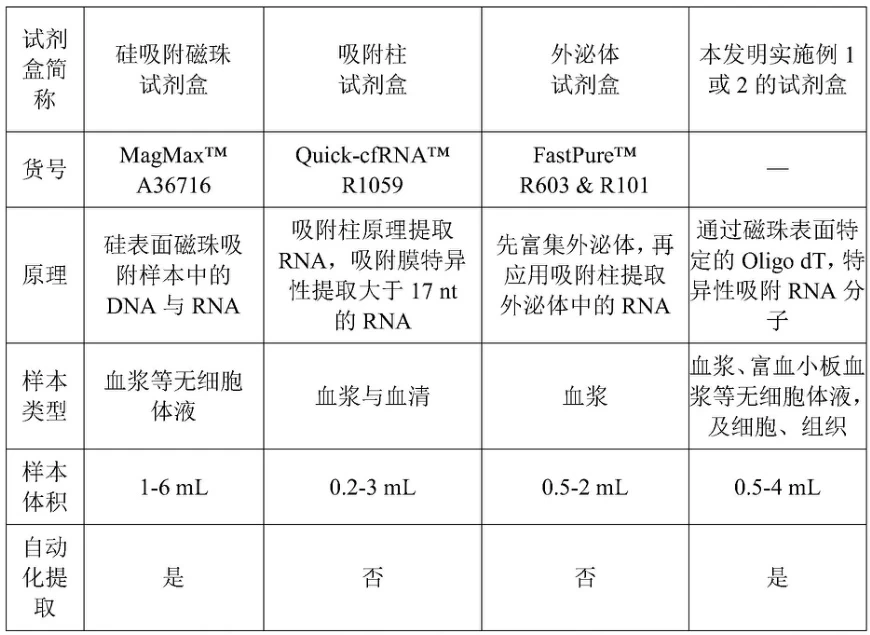

IV. Technology Comparison Matrix

| Kit Type | Mechanism | Sample Suitability | Throughput |

|---|---|---|---|

| Spin-column | Silica membrane adsorption | Tissues, cells, blood | Medium (1–24 samples) |

| Magnetic beads | Oligo-dT/silica binding | Biofluids, automation | High (96-well plates) |

| TRIzol-based | Phase separation | Tough tissues (plant/fungal) | Low |

| Exosome-specific | Pre-enrichment + binding | Plasma/serum | Specialized |

(Source: Patent analysis )

V. Sample-Specific Adaptation

A. Challenging Matrices

| Sample Type | Technical Solution | Yield Optimization |

|---|---|---|

| FFPE tissues | Xylene deparaffinization + proteinase K | 80% recovery vs. fresh |

| Plasma/Serum | Carrier RNA (e.g., MS2 bacteriophage RNA) | 5–100 ng/mL detection |

| Microbiomes | Dual DNase/RNase treatment | Host RNA depletion |

B. Low-Input Systems

- Nucleic acid co-precipitants (GlycoBlue™): Visualize microgram yields

- Laser-capture microdissection: Direct lysis of <10 cells

VI. Quality Control Metrics

Post-extraction validation:

- Integrity: RIN >7.0 (Bioanalyzer)

- Purity: A260/A280 = 1.9–2.1; A260/A230 >2.0

- Contamination: <0.01% genomic DNA (gDNA PCR)

- Functionality: RT-PCR Ct values <30 for housekeeping genes

(Fig. 3: QC Workflow)

Description: Bioanalyzer electrophoresis gel (top) showing intact rRNA bands. Spectrophotometer trace (bottom) with purity ratios.

VII. Application-Specific Kits

| Downstream Use | Kit Features | Commercial Examples |

|---|---|---|

| Single-cell RNA-seq | Cell lysis + poly-A selection | 10x Genomics Chromium |

| Viral diagnostics | Viral capsid disruption buffers | QIAamp Viral RNA Mini |

| Plant RNA isolation | Polysaccharide/polyphenol removal | RNeasy Plant Mini |

| miRNA profiling | Small RNA retention technology | miRNeasy |

VIII. Technical Limitations & Solutions

| Challenge | Cause | Mitigation Strategy |

|---|---|---|

| RNA degradation | RNase contamination | RNase inhibitors in buffers |

| Low yield | Incomplete lysis | Mechanical disruption enhancement |

| gDNA contamination | Inefficient removal | On-column DNase digestion |

| Inhibitor carryover | Polysaccharides/phenols | Ethanol precipitation |

IX. Future Directions

Emerging Innovations

- Automated microfluidics: Chip-based extraction (90 sec processing)

- CRISPR-based purification: Cas13-RNA complexes for targeted isolation

- Point-of-care integration: Lyophilized reagents for field diagnostics

Market Evolution

| Technology Wave | Timeline | Impact |

|---|---|---|

| Organic extraction | 1980s | Phenol-chloroform phase separation |

| Solid-phase systems | 1990s | Silica spin columns |

| Paramagnetic particles | 2000s | High-throughput automation |

| Sequence-specific capture | 2020s | Oligo-functionalized nanomaterials |

“RNA extraction kits transformed molecular biology from artisanal biochemistry to industrialized precision—democratizing access to RNA’s transient molecular intelligence.”

— Nature Methods, 2025

Data sourced from publicly available references. For collaboration inquiries, contact: chuanchuan810@gmail.com.