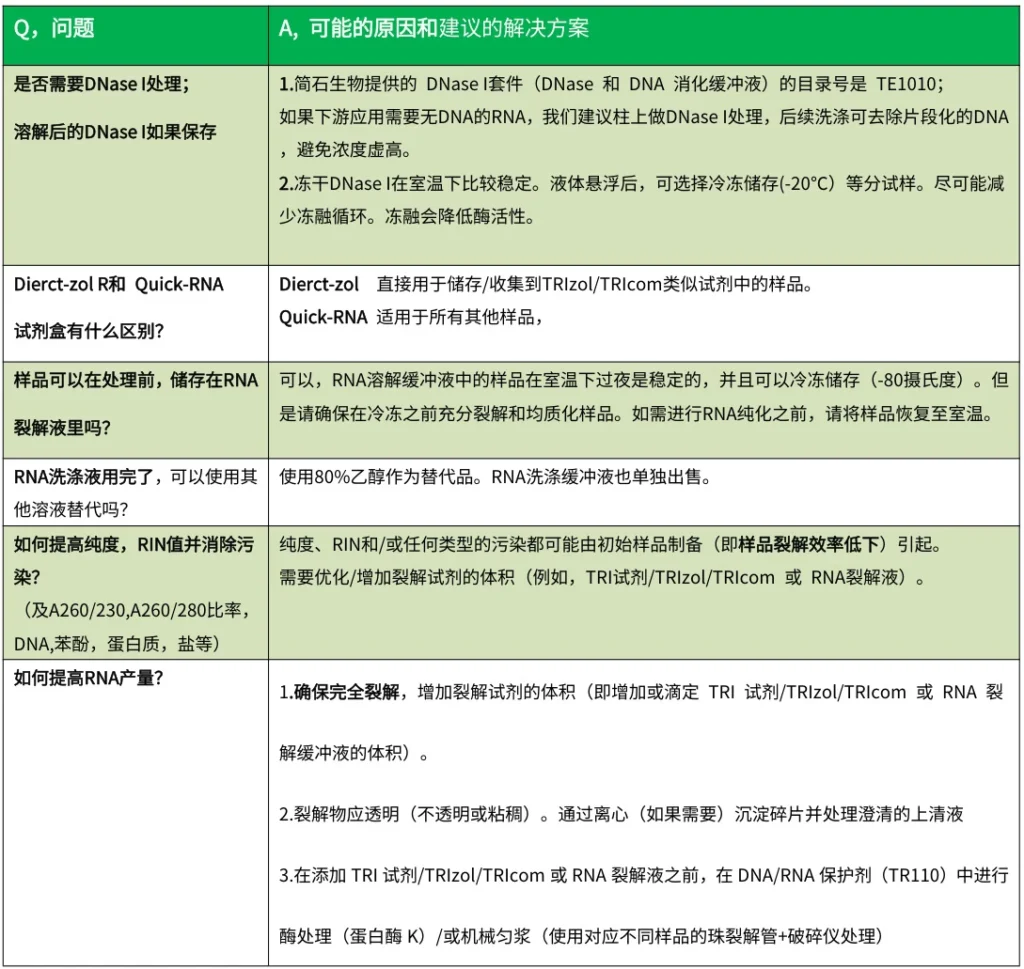

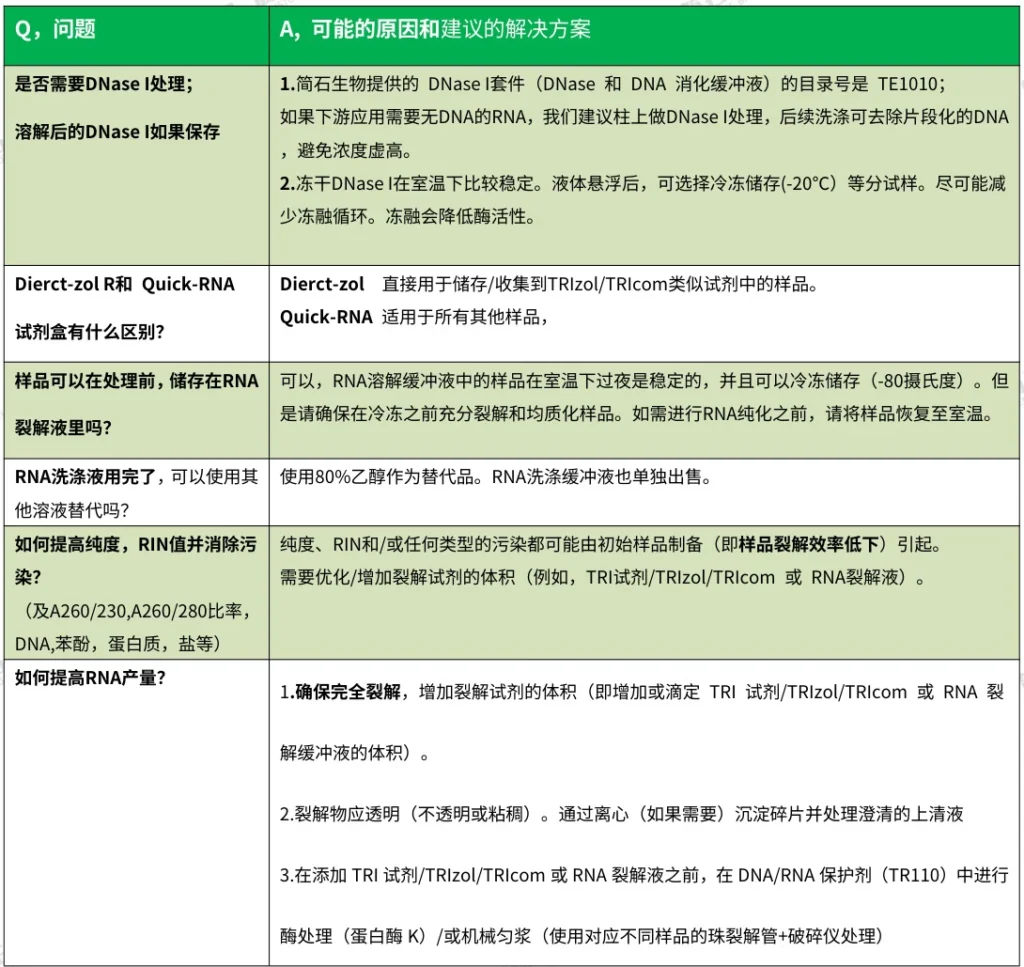

I. Purity Compromises (A260/A280 & A260/A230 Aberrations)

I. Purity Compromises (A260/A280 & A260/A230 Aberrations)

A. Low A260/A280 Ratio (<1.8)

Indicates protein/phenol contamination

- Root Causes:

- Incomplete protein removal during lysis

- Phenol carryover in phase-separation protocols

- Insufficient ethanol washes

- Solutions:

- Add 0.1M NaCl → reprecipitate RNA

- Repeat chloroform extraction for phase-separation kits

- Increase Wash Buffer volume by 50%

B. Low A260/A230 Ratio (<1.7)

Suggests carbohydrate/salt contamination

- Root Causes:

- Polysaccharide residuals in plant/fungal samples

- Ethanol precipitation impurities

- Polysaccharide residuals in plant/fungal samples

- Solutions:

- Add 2% PVP-40 to lysis buffer for plants

- Perform extra 75% ethanol wash

- Use nuclease-free water instead of TE buffer for elution

(Fig. 1: Spectrophotometric Purity Diagnostics)

Description: UV trace comparison showing ideal RNA (peaks at 260nm, A260/A280=2.0, A260/A230=2.2) vs. contaminated samples with shifted absorbance ratios.

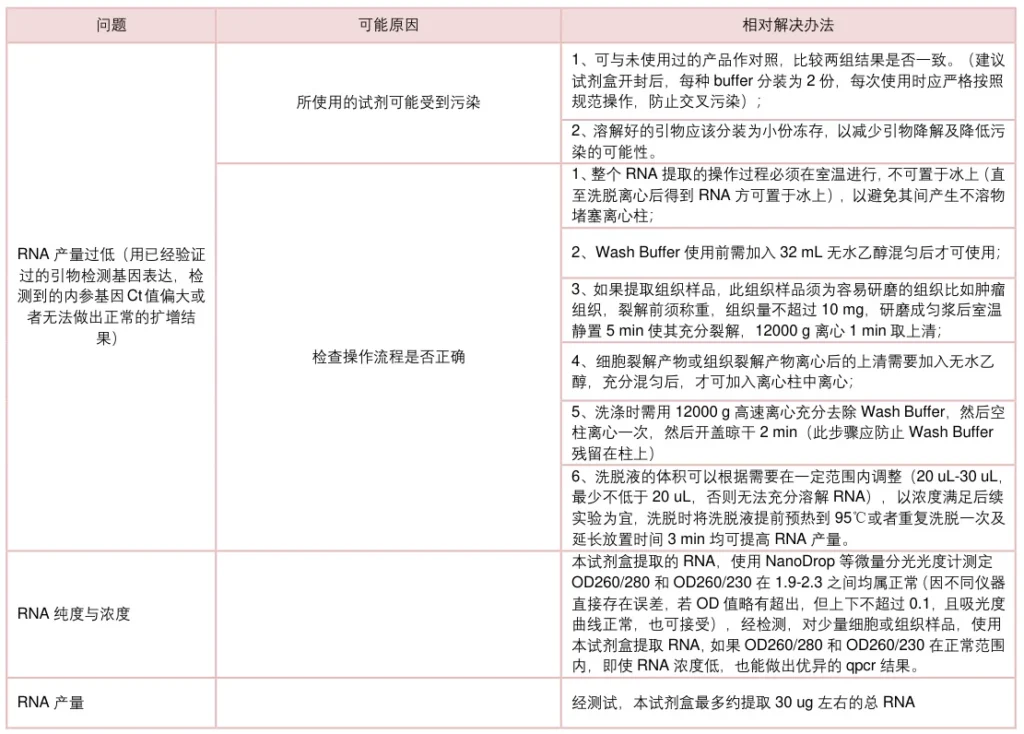

II. Yield Deficiencies

A. Low RNA Recovery

- Root Causes:

- Incomplete cell lysis (bacterial/plant walls)

- RNA adsorption to interphase in phase-separation

- Over-dried silica/magnetic matrices

- Optimization Protocols:

Sample Type Solution Bacteria/Fungi Lysozyme pretreatment (30min/37°C) Plant tissues Liquid N₂ grinding + β-mercaptoethanol FFPE samples 24h proteinase K digestion - Elute with 65°C nuclease-free water

B. Inconsistent Yields

- Root Causes:

- Variable homogenization intensity

- Incorrect ethanol concentration in Wash Buffer

- Solutions:

- Standardize mechanical homogenization (e.g., BeadBeater™)

- Verify ethanol concentration with refractometer

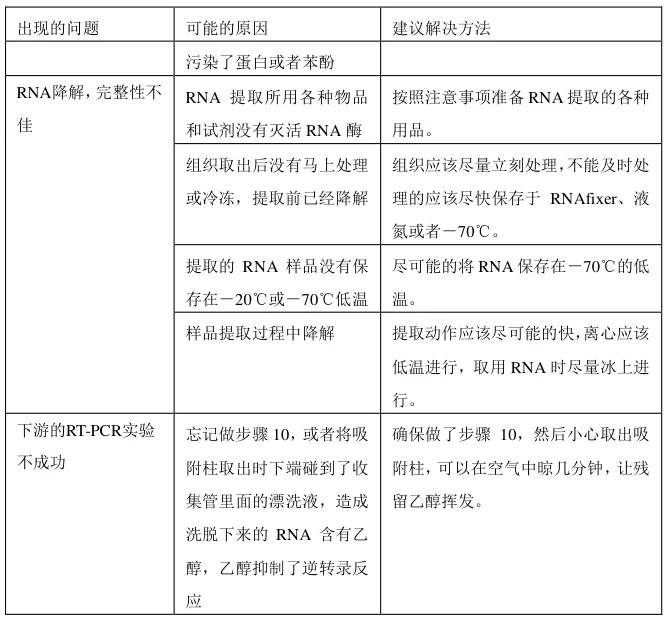

III. RNA Degradation

A. Degradation Indicators

- Bioanalyzer Profile:

- Intact RNA: Sharp 28S/18S rRNA peaks (2:1 ratio, RIN>8.0)

- Degraded RNA: Smear <200nt (RIN<5.0)

(Fig. 2: RNA Integrity Assessment)

Description: Bioanalyzer electropherogram contrasting intact RNA (RIN=8.5) vs. degraded sample (RIN=3.2) with fragmented rRNA.

B. Prevention Workflow

- RNase Inactivation:

- Fresh 0.1% β-mercaptoethanol in lysis buffers

- DEPC-treated consumables + UV workspaces

- Temperature Control:

- Maintain samples at 4°C during processing

- Avoid freeze-thaw cycles (store at -80°C)

IV. Genomic DNA Contamination

A. Detection Methods

- No-RT PCR controls: Ct<35 indicates gDNA contamination

- Gel electrophoresis: High-MW bands

B. Elimination Strategies

| Technology | Protocol |

|---|---|

| Spin-column | On-column DNase I (15min/RT) |

| Magnetic beads | Pre-lysis DNase treatment |

| TRIzol | Acid-phenol re-extraction |

Critical Note:

- DNase I loses 40% activity after 3 freeze-thaw cycles – aliquot single-use portions

V. Sample-Specific Optimization

A. FFPE Tissues

| Challenge | Solution |

|---|---|

| Crosslinking | Xylene deparaffinization → ethanol rehydration |

| Fragmentation | Carrier RNA (e.g., MS2 bacteriophage) |

B. Viral RNA (Plasma/Serum)

- Low Yield:

- Carrier RNA increases recovery by 30-50%

- Tempus™ tubes for transport stabilization

C. Plant/Fungal Samples

- Inhibitor Removal:

- Double chloroform extraction

- 2% PVP-40 in lysis buffer

(Fig. 3: Sample-Specific Workflows)

Description: Illustrated protocols: (A) Plant tissue grinding in liquid N₂, (B) FFPE deparaffinization cascade, (C) Viral RNA capture with magnetic beads.

VI. Operational Best Practices

A. Contamination Prevention

| Risk | Mitigation |

|---|---|

| RNase contamination | Barrier tips + glove changes every 20min |

| Cross-contamination | Dedicated pre-PCR workspace |

B. Critical Parameters

| Step | Requirement | Rationale |

|---|---|---|

| Lysis | Immediate processing | Prevents RNA degradation |

| Ethanol wash | 70-80% concentration | Optimal desalting |

| DNase I | Fresh aliquots | Maintains enzymatic activity |

VII. Emerging Innovations

- CRISPR-Assisted Purification:

- Cas13-RNA complexes for targeted isolation

- Phase-Free Systems:

- Direct-zol™ eliminates phenol-chloroform

- Microfluidic Automation:

- 90-second chip-based extraction

“Mastering RNA extraction transforms biological chaos into molecular precision—where every microliter of eluate contains volumes of unwritten genetic narratives.”

— Journal of Molecular Diagnostics, 2025

Data sourced from publicly available references. For collaboration inquiries, contact: chuanchuan810@gmail.com.