I. Foundational Principles of RNA Stability

I. Foundational Principles of RNA Stability

RNA’s inherent structural vulnerability requires systematic protection against ubiquitous ribonucleases (RNases) and environmental stressors:

- Chemical Vulnerability

- RNA’s 2′-hydroxyl group and single-stranded regions create sites for enzymatic cleavage

- Alkaline conditions (>pH 8.0) accelerate phosphodiester bond hydrolysis

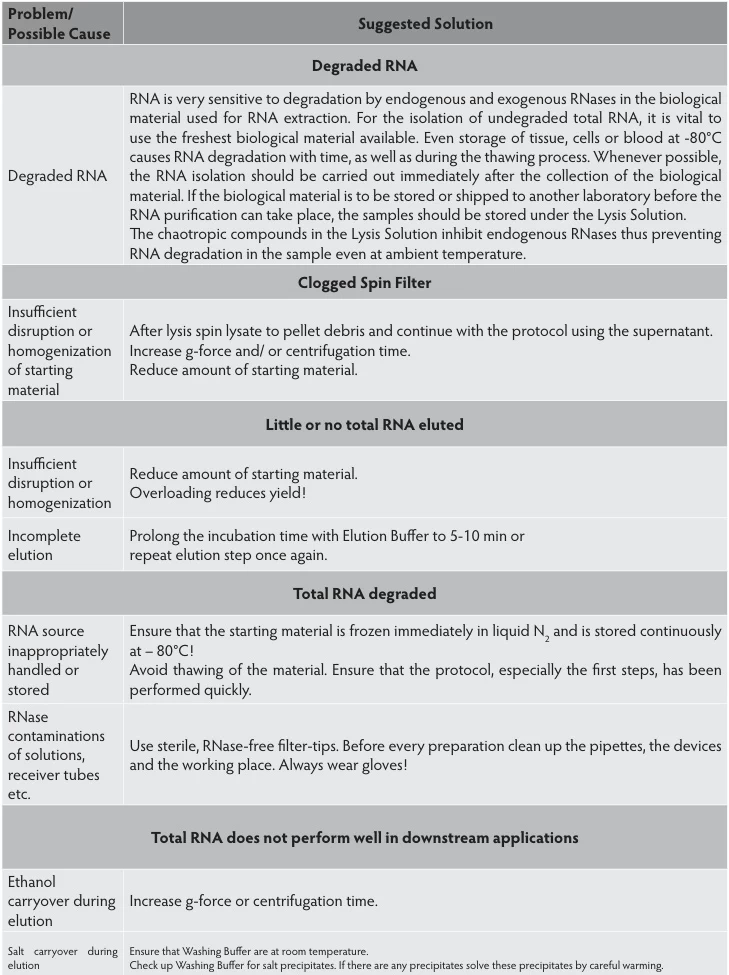

(Fig. 1: Molecular structure highlighting RNA degradation hotspots)

Description: 3D visualization of RNA backbone with RNase cleavage sites (red) and vulnerable bases (yellow).

- RNase Persistence

- Endogenous RNases remain active at 0°C and regain function after denaturation unless permanently inactivated

- Human skin sheds RNases contaminating surfaces and instruments

II. Pre-Extraction Safeguards

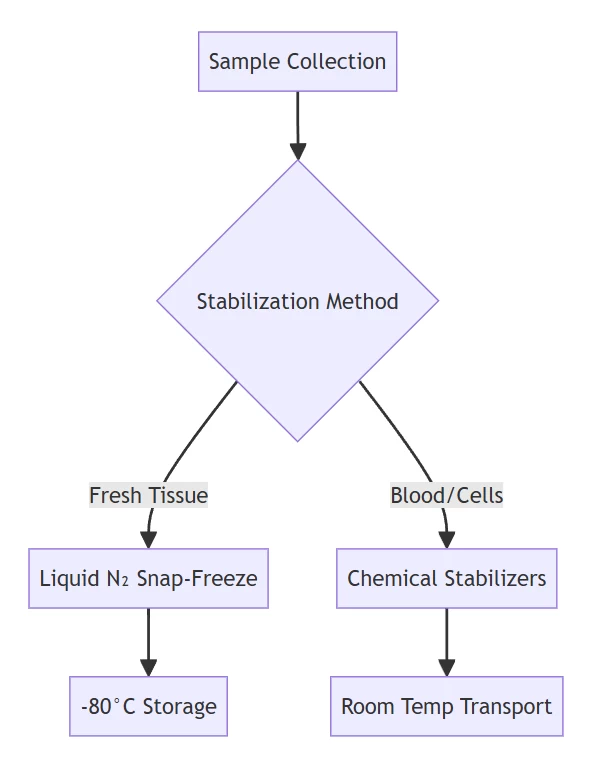

A. Sample Acquisition & Stabilization

| Sample Type | Optimal Protocol | Scientific Rationale |

|---|---|---|

| Tissues | Snap-freeze in liquid N₂; store at -80°C | Halts enzymatic activity within seconds |

| Clinical Specimens | PAXgene/RNAfixer immersion | Denatures RNases at room temperature |

| Cellular Samples | Direct lysis in chaotropic buffers | Immediate RNase inactivation |

B. RNase-Free Workspace Preparation

- Surface Decontamination:

- Treat benches with 0.1% DEPC solution for 12 hours followed by autoclaving

- Use RNase-specific decontaminants (e.g., RNaseZap®) before each experiment

- Consumable Treatment:

- Soak tips/tubes in 0.1% DEPC-H₂O for 2 hours, then autoclave

- Pre-packaged RNase-free consumables recommended for critical applications

III. Extraction Phase Protection

A. Lysis Optimization

- Chaotropic Agents:

- Guanidinium thiocyanate (4M) denatures RNases irreversibly

- Acidic phenol (pH 4.5-5.5) partitions RNases into organic phase

- Mechanical Disruption:

- Cryogenic grinding at <-150°C prevents enzymatic activation

-

- Bead-beating duration limited to ≤90 seconds to avoid heat generation

(Fig. 2: Phase separation in phenol-chloroform extraction)

Description: Diagram showing RNA isolation in RNase-free aqueous phase (top), contaminants in interphase/organic layer.

- Bead-beating duration limited to ≤90 seconds to avoid heat generation

B. Temperature Control Protocol

Process Step Temperature Duration Homogenization 4°C <5 minutes Phase Separation 4°C Centrifugation at 12,000g RNA Precipitation -80°C 30 minutes maximum Pellet Washing -20°C Ethanol pre-chilled C. Inhibitor Applications

- Proteinase K: Essential for FFPE samples (incubate 24h at 56°C)

- RNase Inhibitors: Add 1U/μL recombinant inhibitors during elution

- β-Mercaptoethanol (0.1%): Reduces disulfide bonds in RNases

IV. Post-Extraction Integrity Management

A. Precipitation Enhancement

- Co-precipitants:

- Glycogen (1μg/μL) improves recovery of low-concentration RNA

- Linear acrylamide prevents pellet over-drying

- Solvent Optimization:

- Sodium acetate (0.3M final conc., pH 5.2) with 2.5 volumes ethanol

B. Storage & Handling

Condition Duration Preservation Additives Short-term 1 week -20°C with 0.1 mM EDTA Long-term >1 month -80°C with RNase inhibitors Transport 7 days RNAstable® at room temperature Critical Practice: Aliquot RNA to avoid freeze-thaw cycles (<3 cycles maximum)

V. Quality Control & Troubleshooting

A. Degradation Detection Methods

Technique Intact RNA Indicator Degradation Warning Bioanalyzer RIN ≥8.0; 28S:18S=2:1 RIN ≤6.0; DV200<30% Agarose Gel Sharp ribosomal bands Smear below 1,000 nt Spectrophotometry A260/A280=1.8-2.0; A260/A230>2.0 Ratio deviations >10% (Fig. 3: Bioanalyzer comparison of intact vs. degraded RNA profiles)

Description: Electropherogram showing ideal 28S/18S peaks (blue) versus degraded sample (red smear).B. Common Failure Modes & Solutions

Problem Root Cause Corrective Action Low Yield Incomplete lysis Increase mechanical disruption; add β-mercaptoethanol DNA Contamination Insufficient DNase Column-integrated digestion (37°C/15 min) Organic Residues Incomplete washing Add 25% ethanol wash volume; extend centrifugation Degradation Temperature lapse Monitor cold chain; use pre-chilled equipment

VI. Advanced System Solutions

A. Next-Generation Stabilizers

- RNAstable®: Anhydrobiotic technology for room-temperature storage

- RNAlater-ICE: -20°C-compatible chemical RNase inactivation

B. Automated Platforms

- Microfluidic Systems:

- Integrated lysis-to-elution in <20 minutes with <4°C thermal control

- Robotic Handlers:

- Closed-system extraction with UV-decontaminated chambers

(Fig. 4: Microfluidic RNA extraction chip with temperature zones)

Description: Chip architecture showing cold lysis (4°C), binding (22°C), and elution (4°C) compartments.

- Closed-system extraction with UV-decontaminated chambers

Conclusion: The RNA Integrity Framework

Minimizing degradation requires a three-phase approach:

- Preemptive Neutralization:

- DEPC treatment of consumables

- Immediate sample stabilization

- Process Rigor:

- Continuous temperature control (<8°C)

- Phase-lock separation techniques

- Post-Isolation Vigilance:

- Aliquot storage at -80°C

- RIN-based quality thresholds

“RNA integrity management is not merely technique – it’s a holistic discipline combining biochemical precision, thermal discipline, and uncompromising contamination control.”

— Molecular Pathology ReviewFuture innovations will focus on integrated systems combining stabilization, extraction, and QC in single-use cartridges with real-time degradation monitoring.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.

-

- Cryogenic grinding at <-150°C prevents enzymatic activation

- Chaotropic Agents: