I. Foundational Principles of RNA Optimization

I. Foundational Principles of RNA Optimization

Effective RNA extraction balances yield, purity, and integrity through rigorous control of critical variables:

- RNase Elimination

- Use chaotropic agents (guanidinium thiocyanate) to denature RNases irreversibly during cell lysis

- Treat surfaces with RNase decontamination sprays and use certified RNase-free consumables

(Fig. 1: RNase inactivation mechanism)

Description: Molecular visualization showing guanidinium ions disrupting RNase tertiary structure.

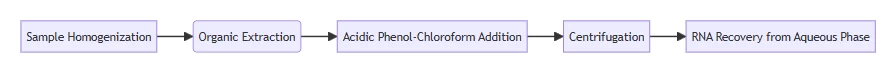

- Phase Separation Dynamics

- Maintain pH <7.0 to partition RNA into aqueous phase while trapping DNA/proteins in interphase

II. Step-by-Step Optimization Protocols

A. Sample-Specific Lysis Optimization

Sample Type Optimal Lysis Method Critical Modifications Plant Tissues CTAB buffer + β-mercaptoethanol Removes polyphenols/polysaccharides FFPE Samples Proteinase K (56°C, 24h) Extended digestion for crosslink reversal Whole Blood PAXgene tubes Prevents hemoglobin contamination Adipose Tissue Chloroform washes (2× volume) Eliminates lipid interference B. Binding & Wash Enhancement

- Silica-Matrix Optimization

- Increase chaotropic salt concentration by 15% for viscous samples to improve RNA binding

- Centrifuge at 4°C to prevent RNA degradation during purification

(Fig. 2: RNA binding to silica membrane)

Description: SEM micrograph showing RNA (blue) adsorbed onto silica fibers in spin column.

- Contaminant Removal

- Add 500 μL ethanol-containing RW2 buffer in two sequential washes (12,000g × 20 sec)

- Extend centrifugation to 2 minutes for complete ethanol evaporation

C. Precipitation & Elution Advances

- Low-Yield Solutions:

- Add 1 μg glycogen or linear acrylamide as co-precipitant

- Reduce elution volume to ≤30 μL RNase-free water for higher concentration

- Integrity Preservation:

- Aliquot RNA and store at -80°C with RNase inhibitors (e.g., RNAsin)

III. Quality Control & Troubleshooting

A. Spectrophotometric Standards

Parameter Optimal Value Corrective Action A260/A280 1.8–2.0 Add phenol-chloroform re-extraction if <1.7 A260/A230 >2.0 Increase ethanol wash volume by 25% Concentration >50 ng/μL Use carrier RNA in precipitation step B. Integrity Validation

- Electrophoretic Analysis:

- Verify 28S:18S rRNA ratio ≥1.5:1 on denaturing agarose gels

- Bioanalyzer Profiling:

- Require RIN >7 for RNA-seq applications

(Fig. 3: Bioanalyzer output of high-integrity RNA)

Description: Electropherogram showing sharp 28S/18S peaks (RIN=9.2) vs. degraded sample (smear).

- Require RIN >7 for RNA-seq applications

IV. Advanced Method Comparison

Technology Yield (ng/mg tissue) Best Applications TRIzol®/Chloroform 80–120 High-yield total RNA Silica Columns (RNeasy®) 60–100 Clinical diagnostics Magnetic Beads 40–80 High-throughput automation CTAB-Phenol 150–200 Plant/fungal samples

V. Emerging Innovations

- Microfluidic Integration:

- Single-cell RNA capture chips with picoliter-scale lysis chambers

- On-chip DNase treatment eliminating separate digestion steps

- Automated Liquid Handlers:

- 45-minute walkaway protocols with temperature-controlled centrifugation

- Cryo-Preservation Alternatives:

- RNAfixer stabilization for room-temperature transport

(Fig. 4: Microfluidic RNA extraction device)

Description: Chip design showing cell lysis, binding, and elution zones with integrated QC.

Conclusion: The Optimization Roadmap

Maximize RNA quality through:

- Sample-Specific Lysis: Match buffer systems to tissue biology

- Phase Control: Maintain acidic pH during organic extraction

- Precision Precipitation: Use co-precipitants for low-concentration samples

- Integrity Verification: Combine spectrophotometry and electrophoretic analysis

- Cold Chain Integrity: Continuous ≤-80°C storage with minimal freeze-thaw cycles

“RNA extraction remains the molecular cornerstone where chemical precision meets biological complexity – demanding optimization at every interface between test tubes and living systems.”

— Genomic Technology ReviewFuture advancements will focus on integrated systems combining extraction, quantification, and library preparation in closed microfluidic platforms.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.

- Maintain pH <7.0 to partition RNA into aqueous phase while trapping DNA/proteins in interphase

II. Step-by-Step Optimization Protocols

A. Sample-Specific Lysis Optimization

Sample Type Optimal Lysis Method Critical Modifications Plant Tissues CTAB buffer + β-mercaptoethanol Removes polyphenols/polysaccharides FFPE Samples Proteinase K (56°C, 24h) Extended digestion for crosslink reversal Whole Blood PAXgene tubes Prevents hemoglobin contamination Adipose Tissue Chloroform washes (2× volume) Eliminates lipid interference B. Binding & Wash Enhancement

- Silica-Matrix Optimization

- Increase chaotropic salt concentration by 15% for viscous samples to improve RNA binding

- Centrifuge at 4°C to prevent RNA degradation during purification

(Fig. 2: RNA binding to silica membrane)

Description: SEM micrograph showing RNA (blue) adsorbed onto silica fibers in spin column.

- Contaminant Removal

- Add 500 μL ethanol-containing RW2 buffer in two sequential washes (12,000g × 20 sec)

- Extend centrifugation to 2 minutes for complete ethanol evaporation

C. Precipitation & Elution Advances

- Low-Yield Solutions:

- Add 1 μg glycogen or linear acrylamide as co-precipitant

- Reduce elution volume to ≤30 μL RNase-free water for higher concentration

- Integrity Preservation:

- Aliquot RNA and store at -80°C with RNase inhibitors (e.g., RNAsin)

III. Quality Control & Troubleshooting

A. Spectrophotometric Standards

Parameter Optimal Value Corrective Action A260/A280 1.8–2.0 Add phenol-chloroform re-extraction if <1.7 A260/A230 >2.0 Increase ethanol wash volume by 25% Concentration >50 ng/μL Use carrier RNA in precipitation step B. Integrity Validation

- Electrophoretic Analysis:

- Verify 28S:18S rRNA ratio ≥1.5:1 on denaturing agarose gels

- Bioanalyzer Profiling:

- Require RIN >7 for RNA-seq applications

(Fig. 3: Bioanalyzer output of high-integrity RNA)

Description: Electropherogram showing sharp 28S/18S peaks (RIN=9.2) vs. degraded sample (smear).

- Require RIN >7 for RNA-seq applications

IV. Advanced Method Comparison

Technology Yield (ng/mg tissue) Best Applications TRIzol®/Chloroform 80–120 High-yield total RNA Silica Columns (RNeasy®) 60–100 Clinical diagnostics Magnetic Beads 40–80 High-throughput automation CTAB-Phenol 150–200 Plant/fungal samples

V. Emerging Innovations

- Microfluidic Integration:

- Single-cell RNA capture chips with picoliter-scale lysis chambers

- On-chip DNase treatment eliminating separate digestion steps

- Automated Liquid Handlers:

- 45-minute walkaway protocols with temperature-controlled centrifugation

- Cryo-Preservation Alternatives:

- RNAfixer stabilization for room-temperature transport

(Fig. 4: Microfluidic RNA extraction device)

Description: Chip design showing cell lysis, binding, and elution zones with integrated QC.

Conclusion: The Optimization Roadmap

Maximize RNA quality through:

- Sample-Specific Lysis: Match buffer systems to tissue biology

- Phase Control: Maintain acidic pH during organic extraction

- Precision Precipitation: Use co-precipitants for low-concentration samples

- Integrity Verification: Combine spectrophotometry and electrophoretic analysis

- Cold Chain Integrity: Continuous ≤-80°C storage with minimal freeze-thaw cycles

“RNA extraction remains the molecular cornerstone where chemical precision meets biological complexity – demanding optimization at every interface between test tubes and living systems.”

— Genomic Technology ReviewFuture advancements will focus on integrated systems combining extraction, quantification, and library preparation in closed microfluidic platforms.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.