Applications of Biogeochemical Cycles in Ecosystems: Case Studies and Innovations

Biogeochemical cycles, as the core mechanism of ecosystems, enable resource regeneration and sustainable development through closed-loop flows of matter and energy. Below is an in-depth analysis of their applications across multiple domains, optimized for clarity and technical precision.

I. Agricultural Ecosystem Models

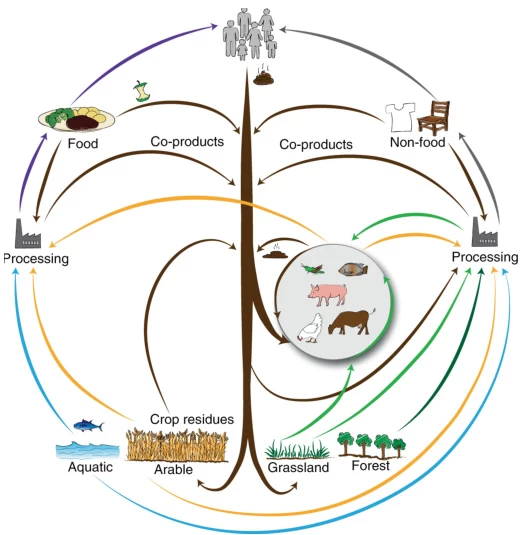

1. Integrated Farming Systems

- Swine-Biogas-Vegetable System:

- Pig manure undergoes anaerobic digestion to produce biogas (energy) and digestate (organic fertilizer), reducing chemical fertilizer use by 30% and increasing crop yields by 15%.

- Example: A 20,000 m² eco-pig farm in Heilongjiang reduces annual carbon emissions by 17,000 tons .

- Fish-Mulberry-Poultry System:

- Fishponds → Pond sludge fertilizes mulberry trees → Silkworms feed on mulberry leaves → Silkworm excrement feeds fish.

- Chickens in mulberry orchards control pests and provide manure, creating a “water-land-air” integrated cycle.

- Rice-Fish Symbiosis:

- Reduces pesticide use by 60% while increasing soil nitrogen content (0.12 → 0.25 g/kg) and rice yields by 8–12% .

2. Microbial-Driven Cycles

- Anaerobic Digestion:

- 1 ton of livestock manure produces 120 m³ biogas (calorific value: 20 MJ/m³), with digestate retaining 85% nitrogen and phosphorus for fertilizer .

- 1 ton of livestock manure produces 120 m³ biogas (calorific value: 20 MJ/m³), with digestate retaining 85% nitrogen and phosphorus for fertilizer .

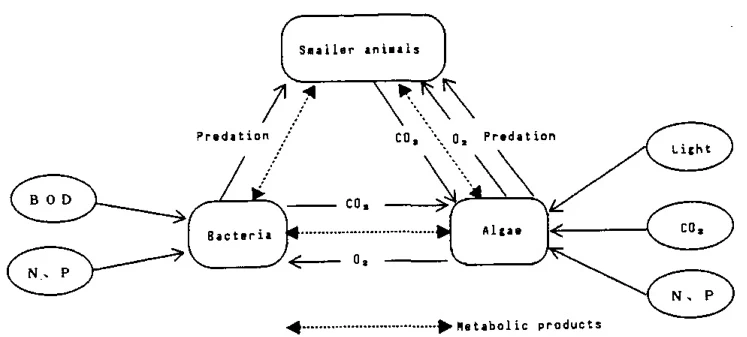

- Biofloc Technology (BFT):

- Heterotrophic bacteria convert ammonia into microbial protein, reducing tilapia feed conversion ratios by 0.3 and ammonia levels by 70% in aquaculture .

II. Aquaculture and Saline Soil Remediation

1. Marine Aquaculture-Salt-Tolerant Plant Cycles

- Fish/shrimp wastewater (N >5 mg/L, P >0.5 mg/L) irrigates suaeda salsa, with biomass converted to biodiesel (18% yield).

- Mangrove wetlands remove >90% heavy metals, as seen in Danzhou’s project (30,000 tons/year organic waste processed; 65% vegetation recovery in saline soils) .

2. Ecological Floating Beds:

- Water hyacinth absorbs nitrogen/phosphorus (1.2 g/m²/day), harvested for vermicomposting → Reduces total nitrogen in water by 50% .

III. Urban Organic Waste Recycling

1. Food Waste Valorization:

- Black soldier fly larvae process 1 ton of food waste into 200 kg protein (45% crude protein) + 600 kg organic fertilizer, reducing landfill carbon footprint by 85% .

- Coffee grounds → Mushroom cultivation substrate (35% conversion rate) → Fungal residues for bioplastics .

2. Wastewater Resource Recovery:

- Microbial fuel cells (MFCs) treat sewage (COD removal >90%) while generating electricity (1.2 W/m³); treated water irrigates urban green spaces .

IV. Industrial Biocycle Innovations

1. Biomass Energy Systems:

- Circulating fluidized bed boilers burn straw (14 MJ/kg) to generate steam (9.8 MPa/540°C), achieving 38% power efficiency and 75% lower CO₂ emissions vs. coal .

- Artemisinin Synthesis: Engineered yeast (90% non-essential genes deleted) boosts artemisinin titers to 2.5 g/L, cutting costs by 40% .

2. Industrial Symbiosis:

- Kalundborg Eco-Industrial Park:

- Refinery sulfur waste → Gypsum board raw materials (200,000 tons/year).

- Power plant waste heat → Fish farm heating (30% energy savings), achieving 92% material closure .

V. Extreme Environment Life Support

1. Space Closed Ecosystems:

- ESA’s MELiSSA project:

- Anaerobic bacteria convert urine to nitrate (85% efficiency).

- Phototrophic bacteria fix CO₂ (1.2 g/m²/h).

- Wheat provides O₂ (20 g/m²/day), achieving 87% material closure .

2. Polar Greenhouses:

- Antarctic hydroponic systems (200 μmol/m²/s light) grow lettuce (28-day cycle) with 99.7% water reuse, yielding 1.2 tons/year per 100 m² .

VI. Theoretical Frameworks and Models

1. Biogeochemical Modeling:

- DNDC Model: Predicts N₂O emissions (g/ha/day) and soil organic carbon changes (%) with 89% accuracy, enabling 20% nitrogen reduction without yield loss .

- Genome-Scale Metabolic Models:

- Optimize microbial consortia to enhance cellulose degradation (1.8 g/L/h) and reduce acetate byproducts (<0.5 g/L) .

System Performance and Challenges

| Metric | Agriculture | Industry | Urban Systems | Extreme Environments |

|---|---|---|---|---|

| Material Closure Rate | 65–80% | 85–95% | 50–70% | >90% |

| Carbon Reduction | 0.5–2 tCO₂/ha/year | 3–8 tCO₂/10k USD | 0.2–1 tCO₂/person/yr | External energy-dependent |

| Energy Efficiency | 15–25% | 30–45% | 10–20% | 8–12% |

| Key Challenges | Microbial regulation | Process integration | Waste sorting | Long-term stability |

Future Directions

- Smart Systems:

- IoT sensors (pH/EC/DO monitoring) + AI (LSTM models) stabilize biogas production (<5% fluctuation) .

- Synthetic Microbial Consortia:

- Engineered Klebsiella oxytoca + Paracoccus denitrificans triple organic waste degradation rates .

- Water Harvesting:

- Biomimetic fog collectors (inspired by desert beetles) yield 5 L/m²/day in arid regions .

Conclusion

Biogeochemical cycles are reshaping resource utilization paradigms by reconstructing the “producer-consumer-decomposer” triad. Projects like the Yabuli eco-pig farm demonstrate the dual environmental and economic benefits of circular models. By translating natural wisdom into technological solutions, these systems offer a foundational strategy for combating climate change.

Data sourced from public references. For collaborations or domain inquiries, contact: chuanchuan810@gmail.com.