I. Foundational Principles of RNA Contamination Control

I. Foundational Principles of RNA Contamination Control

RNase decontamination is paramount due to the enzyme’s ubiquitous presence and extreme stability. Key biochemical mechanisms include:

- RNase Inactivation Chemistry

- β-mercaptoethanol (0.1-1%) disrupts disulfide bonds in RNases, irreversibly denaturing their catalytic sites

- Guanidinium thiocyanate (>4M concentration) denatures proteins while maintaining RNA integrity

-

- (Fig. 1: Molecular mechanism of RNase inactivation)

Description: 3D visualization showing β-mercaptoethanol disrupting RNase tertiary structure through disulfide bond cleavage.

- (Fig. 1: Molecular mechanism of RNase inactivation)

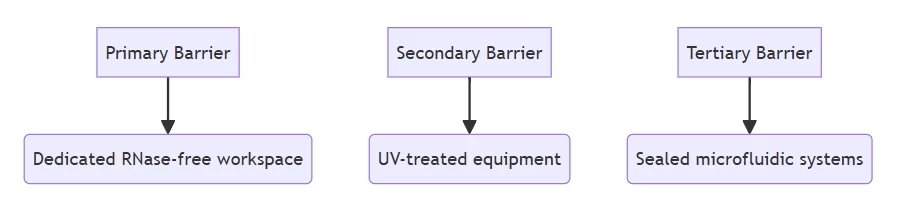

- Environmental Control Hierarchy

- Establish physical isolation zones with positive air pressure

II. Pre-Extraction Phase: Proactive Contamination Prevention

A. Workspace & Equipment Preparation

Surface/Item Decontamination Protocol Scientific Rationale Benchtops RNaseZap® treatment + UV irradiation (30 min) Degrades RNases via alkaline hydrolysis Glassware 180°C baking for 4 hours Thermal denaturation of RNases Plasticware 0.1% DEPC-treated water immersion (2 hr) Carbethoxylation of histidine residues Centrifuges Pre-cool to 4°C; seal rotor buckets Prevents aerosol contamination B. Sample Handling Protocols

- Biological Specimens:

- Snap-freeze tissues in liquid N₂ within 30 seconds of collection

- Preserve liquid samples in RNAlater™/RNAstable® for room-temperature transport

- Personal Protective Equipment:

- Double-glove with frequent changes (every 15 min)

- Wear surgical masks to prevent salivary RNase contamination

(Fig. 2: Contamination vector analysis in RNA workflows)

Description: Infographic ranking contamination sources: skin (42%), aerosols (33%), equipment (25%)

III. Extraction Phase: Critical Control Points

A. Organic Phase Separation Management

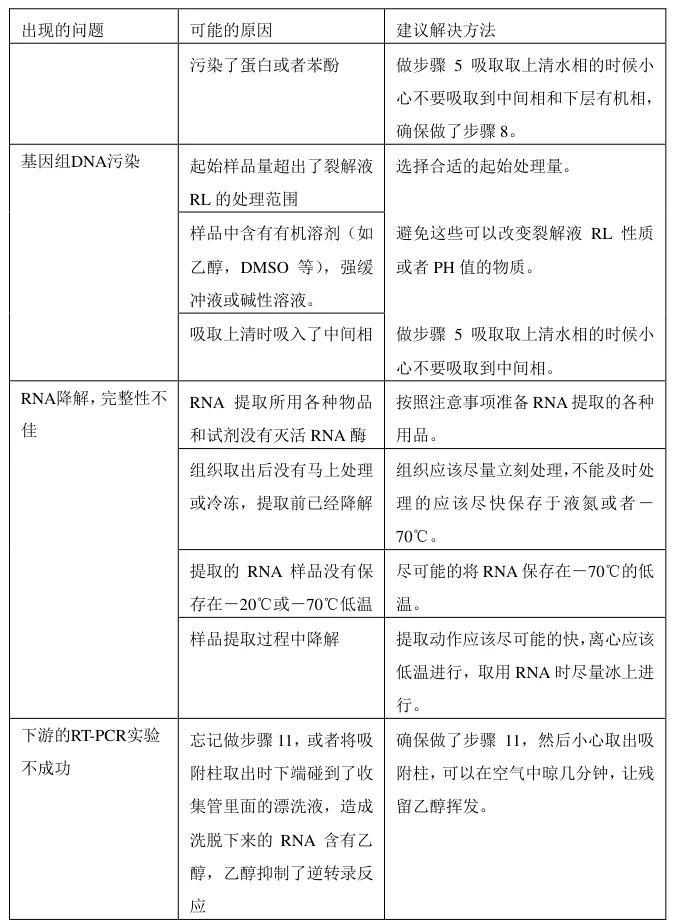

Contaminant Type Detection Sign Corrective Protocol Genomic DNA A260/A280 >2.0 On-column DNase I digestion (37°C/15 min) Phenol residuals A260/A230 <1.8 25% increased ethanol wash volume Protein carryover Precipitated pellet cloudiness Repeat acid-phenol extraction B. Phase-Lock Techniques

- Aqueous Phase Recovery:

- Leave 2mm clearance above interphase during pipetting

- Use phase-lock gel tubes for absolute separation

- Silica Column Optimization:

- Centrifuge at ≤8,000g to prevent membrane rupture

- Validate binding capacity before processing large samples

IV. Post-Extraction Quality Assurance

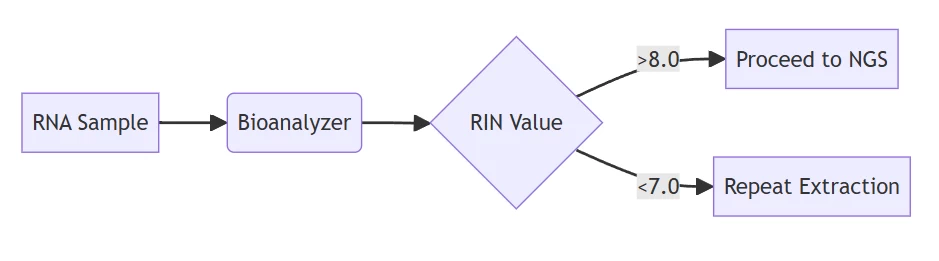

A. Integrity & Purity Validation

Assessment Method Acceptance Criteria Contamination Indicators Bioanalyzer RIN ≥8.0; 28S:18S=2:1 RIN ≤6.0; DV200<30% Spectrophotometry A260/A280=1.8-2.0 Protein/organic deviations PCR amplification Ct ≤30 for housekeeping genes DNA contamination

B. Storage & Stability Protocols

- Short-term: -80°C with RNase inhibitors (RNAsin®) in single-use aliquots

- Long-term: Anhydrobiotic stabilization at room temperature

V. Specialized Sample Contamination Control

A. Challenging Matrices

Sample Type Unique Contaminants Targeted Solutions Plant tissues Polysaccharides/polyphenols CTAB buffer + 2% PVP-40 FFPE samples Formaldehyde crosslinks Extended Proteinase K (24h/56°C) Whole blood Hemoglobin/heme Leukocyte separation filters B. Low-Input Applications

- Microfluidic Isolation:

- Integrated lysis-to-elution in sealed chips

- Picoliter-scale chambers eliminate cross-contamination

(Fig. 3: Microfluidic RNA extraction chip)

Description: Sealed chip architecture with separate lysis (red), binding (blue), and elution (green) chambers.

VI. Advanced System Solutions

A. Automated Platforms

- Robotic Liquid Handlers:

- Enclosed systems with HEPA filtration

- UV decontamination between samples

- Closed-Cartridge Systems:

- Pre-packaged reagent kits with integrated waste

B. Next-Gen Stabilizers

- RNAstable®:

- Water-soluble barriers create anhydrobiotic environment

- Cryo-protective Additives:

- Trehalose maintains RNA integrity during freeze-thaw

Conclusion: The Zero-Contamination Framework

Achieving RNase-free RNA requires:

- Preemptive Neutralization:

- Surface decontamination + chemical inhibitors

- Physical Barriers:

- Dedicated workspaces + sealed systems

- Process Vigilance:

- Phase-lock separation + capacity validation

- Post-Isolation Verification:

- RIN/DV200 thresholds + aliquot storage

“RNA extraction contamination control isn’t a protocol – it’s a holistic discipline requiring relentless attention to molecular enemies at every interface between sample and solution.”

— Journal of Molecular DiagnosticsFuture innovations will focus on AI-driven contamination monitoring systems with real-time degradation alerts.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.