I. Pre-Extraction Phase: Sample Integrity Preservation

I. Pre-Extraction Phase: Sample Integrity Preservation

RNA degradation begins immediately post-collection, necessitating rigorous stabilization protocols:

- RNase Inactivation Strategies

- Treat surfaces with RNase-specific decontaminants (e.g., RNaseZap®) and use certified RNase-free consumables

- Add β-mercaptoethanol (0.1-1%) or DTT to lysis buffers to denature RNases

-

-

- (Fig. 1: Molecular mechanism of RNase inhibition)

Description: 3D visualization showing β-mercaptoethanol disrupting RNase disulfide bonds.

- (Fig. 1: Molecular mechanism of RNase inhibition)

- Sample Handling Protocols

Sample Type Optimal Protocol Critical Modifications Tissues Snap-freeze in liquid N₂ within 30 sec Avoid repeated freeze-thaw cycles Blood PAXgene/RNAstable® tubes Prevent hemolysis Cultured Cells Complete media removal before lysis Residual FBS contains RNases

graph TD

A[Fresh Sample] –> B{Stabilization Method}

B –>|Tissues| C[Liquid N₂ Flash-Freeze]

B –>|Liquid Samples| D[Chemical Stabilizers]

C –> E[-80°C Storage]

D –> F[Room Temp Preservation] -

- —

### **II. Extraction Phase: Yield & Purity Optimization**

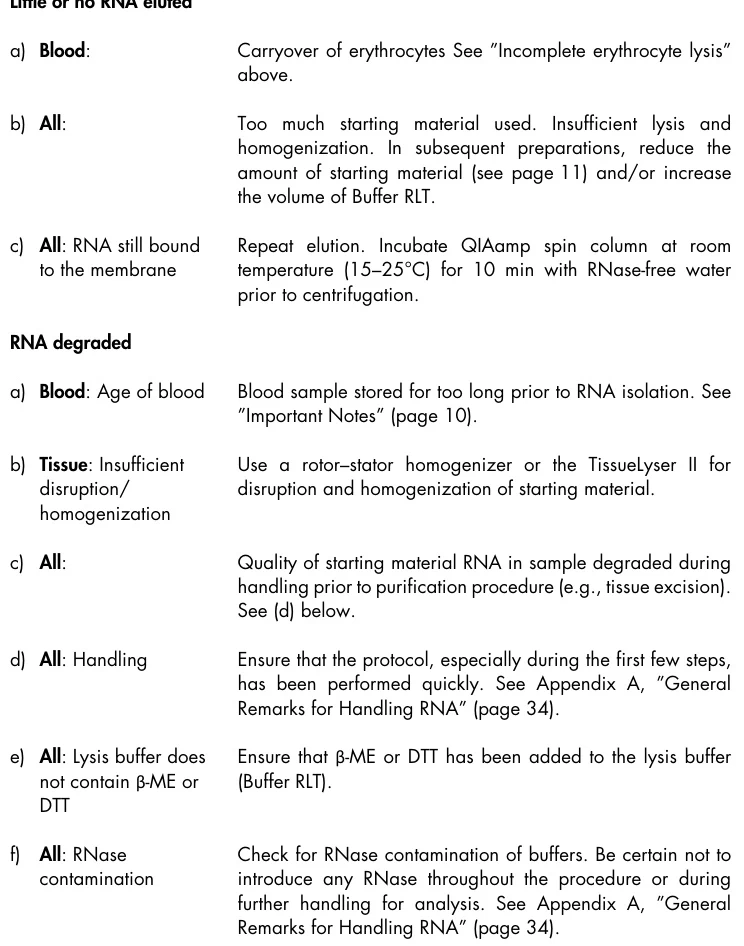

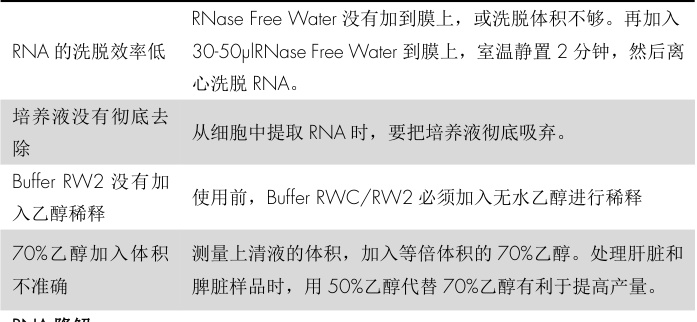

#### **A. Low RNA Yield Solutions**

| **Cause** | **Detection Method** | **Corrective Action** |

|———–|———————-|———————-|

| Insufficient lysis | Visible tissue pellets | Increase mechanical disruption: <br>- Cryogenic grinding with liquid N₂ <span data-key=”6″ class=”reference-num” data-pages=”undefined”>12</span> <br>- Bead-beating ≥90 sec <span data-key=”7″ class=”reference-num” data-pages=”undefined”>9</span> |

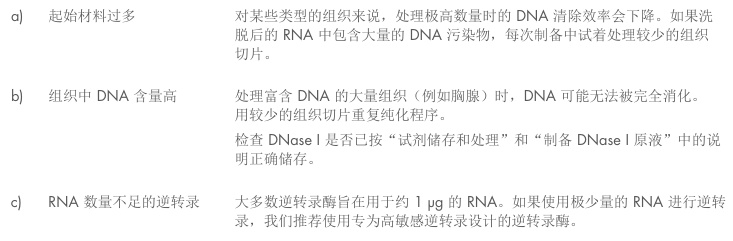

| Excessive starting material | Gel electrophoresis smear | Reduce tissue input by 30-50% <span data-key=”8″ class=”reference-num” data-pages=”undefined”>1</span><span data-key=”9″ class=”reference-num” data-pages=”undefined”>6</span> |

| Incomplete elution | Low A260 readings | Add 30-50µl RNase-free H₂O to membrane <br>Incubate 10 min before centrifugation <span data-key=”10″ class=”reference-num” data-pages=”undefined”>9</span> |

*(Fig. 2: Silica membrane saturation dynamics)*

*Description: SEM micrograph showing optimal (left) vs. insufficient (right) RNA binding to silica matrix.*#### **B. Contamination Management**

1. **Genomic DNA Contamination**:

– Column-integrated DNase treatment (37°C/15 min) <span data-key=”11″ class=”reference-num” data-pages=”undefined”>8</span>

– Design intron-spanning primers for downstream applications <span data-key=”12″ class=”reference-num” data-pages=”undefined”>12</span>

2. **Organic/Particulate Contaminants**:| **A260/A230** | **Contaminant Type** | **Solution** |

|—————|———————-|————–|

| <1.8 | Polysaccharides | CTAB buffer for plant tissues <span data-key=”13″ class=”reference-num” data-pages=”undefined”>14</span> |

| <2.0 | Guanidinium salts | Additional ethanol washes <span data-key=”14″ class=”reference-num” data-pages=”undefined”>8</span> |—

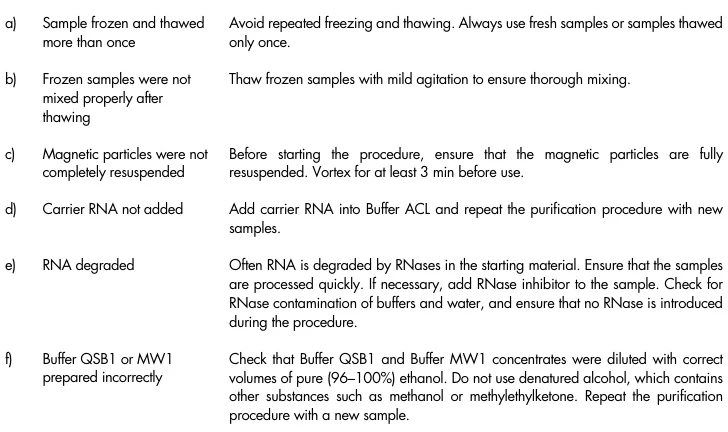

### **III. Post-Extraction Phase: Integrity & Stability**

#### **A. RNA Degradation Prevention**

– **Electrophoretic Validation Standards**:| **Sample Type** | **Intact RNA Indicator** | **Degradation Threshold** |

|—————-|————————–|—————————|

| Mammalian cells | 28S:18S = 2:1 | Ratio <1.0 <span data-key=”15″ class=”reference-num” data-pages=”undefined”>7</span> |

| FFPE tissues | DV200 >30% | DV200 <20% <span data-key=”16″ class=”reference-num” data-pages=”undefined”>6</span> |

“`mermaid

graph LR

A[RNA Sample] –> B(Bioanalyzer)

B –> C{RIN Value}

C –>|>8.0| D[Proceed to NGS]

C –>|<7.0| E[Repeat Extraction]B. Storage & Handling Protocols

Duration Storage Conditions Preservation Additives <1 week -20°C 0.1 mM EDTA >1 month -80°C RNase inhibitors Transport Room temp RNAstable®/Anhydrobiotic tech Critical Practice: Aliquot RNA to limit freeze-thaw cycles to ≤3

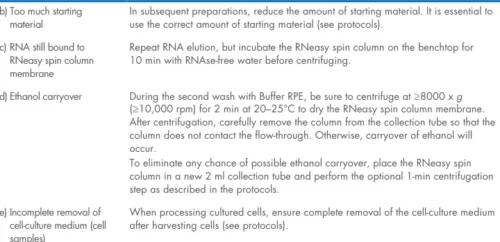

IV. Specialized Sample Optimization

A. Challenging Sample Matrix Solutions

Sample Type Primary Challenge Optimized Protocol Plant tissues Polysaccharide contamination CTAB buffer + 2% PVP-40 Adipose tissue Lipid interference Double-volume chloroform washes FFPE samples Crosslinked RNA Extended Proteinase K digestion (24h/56°C) Whole blood Hemoglobin inhibition Leukocyte separation filters B. Low-Input Applications

- Carrier Enhancement:

- Add 1µg glycogen or linear acrylamide during precipitation

- Reduce elution volume to ≤30µl

- Microfluidic Platforms:

- Integrated extraction with picoliter-scale chambers

(Fig. 3: Microfluidic RNA extraction chip)

Description: Microchannel network with temperature-controlled lysis (4°C) and binding zones (22°C).

V. Quality Control Framework

A. Spectrophotometric Standards

Parameter Acceptable Range Corrective Action A260/A280 1.8-2.0 Phenol-chloroform re-extraction A260/A230 >2.0 25% increased ethanol wash volume Concentration >50 ng/µl Carrier RNA addition B. Electrophoretic Verification

- Agarose Gel Analysis:

- Denaturing gels with sharp 28S/18S ribosomal bands

- RIN/DV200 Validation:

- Require RIN>7 for RNA-seq; DV200>30% for FFPE

Conclusion: The RNA Integrity Preservation Protocol

Achieving high-quality RNA requires addressing three critical dimensions:

- Preemptive RNase Neutralization

- Chemical inhibitors (β-mercaptoethanol/DTT)

- Surface decontamination protocols

- Sample-Specific Lysis Optimization

- Mechanical disruption enhancements

- Contaminant-specific buffers (CTAB for plants)

- Post-Isolation Vigilance

- Aliquoted -80°C storage

- RIN/DV200 quality thresholds

“RNA extraction is not a protocol – it’s a chain of custody where each link must guard against the omnipresent threat of RNase degradation.”

— Molecular Systems BiologyFuture innovations will focus on integrated microfluidic systems performing extraction, QC, and library prep in <30 minutes with real-time degradation monitoring.

Data sourced from publicly available references. For collaboration or domain acquisition inquiries, contact: chuanchuan810@gmail.com.

- Carrier Enhancement: